Laser Engraving Machine Market Report & Forecast 2034

The laser engraving machine market has become a vital component in numerous industries, including advertising, manufacturing, and art. With an increasing demand for precision engraving, customization, and high-quality production, the market is on a rapid growth trajectory. The global laser engraving machine market reached a value of over USD 3.51 Billion in 2024 and is projected to grow at a CAGR of 8.30% between 2025 and 2034, reaching an estimated USD 7.79 Billion by 2034.

Laser Engraving Machine Market Outlook

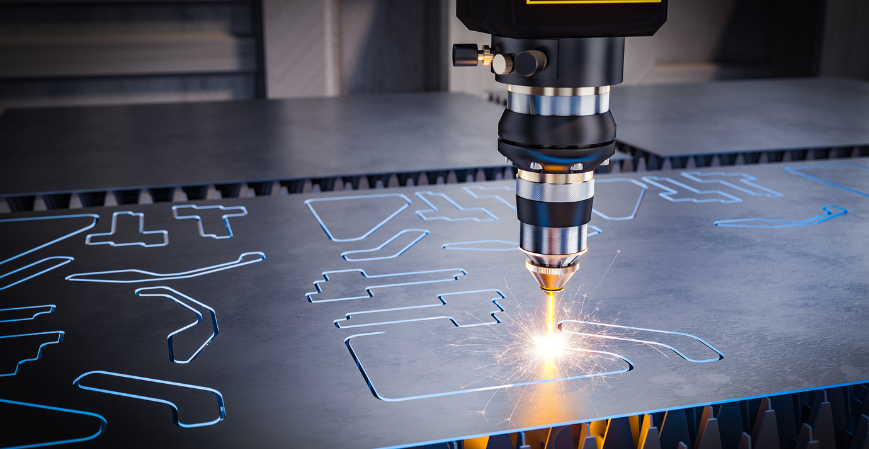

The global laser engraving machine market is experiencing significant growth, driven by increasing demand for customization and precision in various sectors. As industries such as advertising, printing and packaging, and arts and crafts continue to expand, the need for high-quality, efficient, and precise engraving solutions is on the rise. The market is primarily fueled by technological advancements that make these machines more versatile, cost-effective, and user-friendly.

The adoption of laser engraving machines is expanding across industries due to their ability to create intricate designs on a wide range of materials, including metals, plastics, wood, leather, and glass. These machines are crucial for industries requiring detailed and durable marks, such as product branding, personalization of goods, and marking for traceability.

Get Your Free Sample Report with ToC – https://www.expertmarketresearch.com/reports/laser-engraving-machine-market/requestsample

Laser Engraving Machine Market Trends

Growth in Customization and Personalization:

One of the major trends in the laser engraving machine market is the rising demand for customization and personalization across various industries. Consumers today prefer personalized products, whether it’s customized jewelry, engraved gifts, or personalized leather goods. The ability to engrave unique designs on a variety of materials has made laser engraving an ideal solution for this growing trend.

Technological Advancements:

Technological advancements in laser engraving machines are driving the market forward. Innovations like fiber laser technology, CO2 lasers, and diode lasers are offering enhanced precision, speed, and flexibility in engraving. These advancements allow manufacturers to create more complex and detailed designs while improving overall productivity and reducing operational costs.

Integration with Automation and Digitalization:

The trend toward automation and digitalization is also having a major impact on the laser engraving industry. The integration of laser engraving machines with automated systems and robotic technology allows for faster production cycles and higher throughput. Additionally, the use of computer numerical control (CNC) and CAD/CAM software has enabled greater precision and flexibility, allowing manufacturers to create highly intricate designs without the need for manual intervention.

Focus on Eco-Friendly Solutions:

With growing concerns about environmental sustainability, manufacturers are increasingly focusing on eco-friendly solutions. Laser engraving machines are seen as a greener alternative to traditional methods such as mechanical engraving or printing, as they produce less waste and require fewer consumables. This trend is expected to drive the adoption of laser engraving technologies, particularly in regions with stringent environmental regulations.

Increasing Use in Small and Medium-Sized Businesses:

The affordability and accessibility of laser engraving machines have made them an attractive option for small and medium-sized enterprises (SMEs). These businesses can now leverage laser technology to produce high-quality engraved products at a lower cost, leading to the democratization of engraving technology across industries.

Drivers of Growth

Demand for Precision and Customization:

As mentioned, there is an increasing demand for highly precise and customizable products across industries such as advertising, printing, and fashion. Laser engraving machines are ideal for meeting these needs due to their ability to create intricate and durable designs with high accuracy. The demand for customized items, including engraved gifts, personalized clothing, and custom logos on products, is expected to drive market growth.

Increased Industrial Automation:

The rise in industrial automation across sectors such as electronics, automotive, and packaging is boosting the demand for laser engraving machines. These machines can be integrated into automated production lines, enabling high-speed, high-volume production while maintaining precision and quality. The ability to automate the engraving process also improves efficiency and reduces human error.

Cost-Effectiveness and Reduced Operational Costs:

Compared to traditional engraving methods, laser engraving machines offer a more cost-effective solution over the long term. They require fewer consumables, such as inks or blades, and the reduced need for manual labor lowers operational costs. This cost-effectiveness makes laser engraving machines an attractive option for businesses looking to enhance productivity while reducing expenses.

Technological Advancements:

Continuous advancements in laser technology, such as improved laser beam quality, faster engraving speeds, and greater flexibility, are driving the market. Additionally, the development of fiber lasers and other new laser types has expanded the range of materials that can be engraved, further broadening the scope of applications for laser engraving machines.

Expansion of End-Use Industries:

The increasing demand for laser engraving machines from end-use industries such as leather and apparel, printing and packaging, and model making is fueling market growth. The demand for intricate designs and high-quality engraving in these sectors is creating a large market for advanced laser engraving technology.

Technology and Advancements

Fiber Lasers:

Fiber lasers are gaining popularity due to their ability to offer higher energy efficiency, longer lifespan, and better beam quality compared to traditional CO2 lasers. They are particularly well-suited for engraving metal and other hard materials, which makes them ideal for industries such as aerospace, automotive, and electronics.

CO2 Lasers:

CO2 laser technology continues to be widely used for engraving non-metallic materials, including wood, leather, plastic, and glass. CO2 lasers offer versatility and high-speed performance, making them ideal for industries such as advertising, arts and crafts, and packaging.

Automation and Smart Controls:

Advances in automation and smart control systems have significantly improved the efficiency and precision of laser engraving machines. These systems allow for faster setup times, real-time monitoring, and the ability to make adjustments on-the-fly, resulting in a more streamlined and optimized engraving process.

Integration with CAD/CAM Software:

The integration of laser engraving machines with CAD/CAM software has enhanced the design capabilities of engraving systems. This integration allows for complex designs to be translated directly into engraving instructions, enabling manufacturers to produce intricate and customized engravings with ease.

Challenges and Opportunities

challenges:

High Initial Investment:

The initial investment required to purchase and install a laser engraving machine can be significant, particularly for small and medium-sized businesses. While these machines offer long-term savings, the high upfront cost may be a barrier to entry for some companies.

Technical Expertise:

Operating laser engraving machines requires technical expertise, which can be a challenge for businesses without the necessary skill sets. Training and hiring skilled personnel can increase costs for companies entering the market.

Competition from Alternative Technologies:

The laser engraving machine market faces competition from alternative engraving methods, such as mechanical engraving and chemical etching, which may offer lower upfront costs. However, as demand for precision and customization continues to grow, laser engraving is likely to maintain its market position due to its unique advantages.

Opportunities

Opportunities in Emerging Markets:

The laser engraving machine market presents significant opportunities in emerging markets in regions like Asia-Pacific, Latin America, and the Middle East. As industrialization accelerates and consumer demand for customized products increases, these regions are expected to drive growth in the market.

Expansion in End-Use Applications:

The growing adoption of laser engraving across industries such as electronics, packaging, and automotive presents new opportunities for market expansion. As more industries realize the benefits of laser engraving, demand is expected to rise across various sectors.

Laser Engraving Machine Market Segmentation

By Product Type:

CO2 Laser

Fibre Laser

Diode Laser

YAG Laser

By End Use:

Advertising Decoration

Printing and Packaging

Leather and Apparel

Model Making

Arts and Crafts

Others

By Region:

North America (United States, Canada)

Europe (United Kingdom, Germany, France, Italy, Others)

Asia Pacific (China, Japan, India, ASEAN, Australia, Others)

Latin America (Brazil, Argentina, Mexico, Others)

Middle East and Africa (Saudi Arabia, UAE, Nigeria, South Africa, Others)

Key Players

-

Universal Laser Systems, Inc.

-

Trotec Laser GmbH

-

LaserStar Technologies Corporation

-

Epilog Corporation

-

Sintec Optronics Pte Ltd.

Frequently Asked Questions (FAQ)

-

What industries use laser engraving machines?

Laser engraving machines are used in industries such as advertising, printing, leather and apparel, model making, arts and crafts, and more. -

What are the types of lasers used in engraving machines?

The main types of lasers used are CO2 lasers, fiber lasers, diode lasers, and YAG lasers. -

How does a laser engraving machine work?

A laser engraving machine uses focused laser beams to etch designs onto various materials with high precision. -

What are the advantages of laser engraving machines?

Advantages include high precision, customization options, low maintenance, and energy efficiency. -

What are the challenges in the laser engraving machine market?

Challenges include high initial costs, the need for technical expertise, and competition from alternative technologies.

- Vibnix Blog

- Politics

- News

- Liberia News

- Entertainment

- Technology

- Formazione

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness