Epitaxial Wafer Market Report & Forecast 2034

The epitaxial wafer market is on an impressive growth trajectory, with the market valued at approximately USD 5.51 billion in 2024. This growth is projected to continue at a CAGR of 12.30% from 2025 to 2034, with the market expected to reach USD 17.58 billion by 2034. The rapid pace of technological advancements, increasing demand for LEDs, power semiconductors, and MEMS-based devices, as well as expanding applications in various industry verticals, are driving the growth of the epitaxial wafer market.

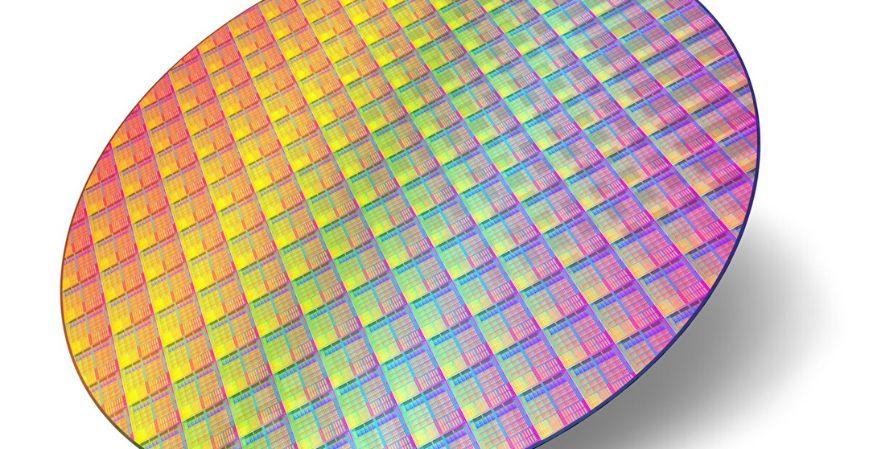

Epitaxial wafers, essential in the semiconductor industry, play a crucial role in enhancing the performance of electronic devices. These wafers, which are used to fabricate high-performance devices, are typically made by a process called epitaxy, where thin layers of material are deposited onto a substrate. This process is crucial for the production of high-quality, durable semiconductors, thus enabling the next generation of electronic devices.

Epitaxial Wafer Market Trends

-

Shift Towards Advanced Electronics: The shift towards advanced electronics and smart technologies is one of the key trends driving the epitaxial wafer market. As consumer demand for high-performance smartphones, wearables, and IoT devices increases, the need for advanced semiconductors grows. Epitaxial wafers play a crucial role in enabling the manufacturing of these sophisticated devices.

-

Growing Demand for LEDs: The LED market has been a significant driver of growth in the epitaxial wafer sector. LEDs, which are widely used in lighting, displays, and signage, require high-quality epitaxial wafers for manufacturing. As the global demand for energy-efficient and long-lasting lighting solutions increases, the demand for epitaxial wafers in the LED market continues to rise.

-

Power Semiconductor Applications: The demand for power semiconductors, particularly for electric vehicles (EVs) and renewable energy solutions, is on the rise. Epitaxial wafers are essential in the production of power semiconductors, which are critical for controlling electrical energy in various applications such as automotive power systems and solar power inverters. This growing demand for power semiconductors is a major factor propelling the epitaxial wafer market.

-

Miniaturization of MEMS Devices: The trend towards the miniaturization of MEMS (Micro-Electro-Mechanical Systems) devices is another crucial trend in the epitaxial wafer market. As MEMS devices become smaller and more sophisticated, the need for high-quality epitaxial wafers that support these devices’ performance continues to increase. MEMS-based applications are growing rapidly in sectors like healthcare, automotive, and consumer electronics.

Get Your Free Sample Report with ToC – https://www.expertmarketresearch.com/reports/epitaxial-wafer-market/requestsample

Drivers of Growth

-

Technological Advancements in Semiconductor Manufacturing: The continuous evolution of semiconductor manufacturing technologies is a primary driver of the epitaxial wafer market. As semiconductor technology advances, the demand for higher-performance epitaxial wafers increases. Innovations such as 3D semiconductor stacking, AI-enhanced semiconductors, and quantum computing drive the demand for epitaxial wafer products.

-

Rising Demand for Energy-Efficient Solutions: With growing concerns about energy efficiency and sustainability, energy-efficient lighting solutions, such as LEDs, are becoming more popular. As LEDs require epitaxial wafers for their manufacturing, this rise in demand for energy-efficient lighting products boosts the market.

-

Adoption of Electric Vehicles (EVs): The growing adoption of electric vehicles (EVs) worldwide is creating a huge demand for power semiconductors and power electronics, which require epitaxial wafers. The use of epitaxial wafers in the manufacturing of power devices for EVs, chargers, and energy storage systems is one of the key growth drivers in the epitaxial wafer market.

-

Increased Demand for Consumer Electronics: With the proliferation of smartphones, smartwatches, tablets, and laptops, there is a heightened demand for semiconductors, particularly for the fabrication of chips that power these devices. As these consumer electronics become more powerful and feature-rich, the demand for high-quality epitaxial wafers to manufacture these semiconductors continues to grow.

Technology and Advancements

-

Heteroepitaxy vs. Homoepitaxy: The two main types of epitaxial wafers are heteroepitaxy and homoepitaxy. Heteroepitaxy involves the growth of a different material on the substrate, while homoepitaxy involves the use of a substrate of the same material. Both technologies are advancing, with heteroepitaxy enabling the production of more complex and high-performance devices. Innovations in both areas are driving improvements in epitaxial wafer quality and production efficiency.

-

Advances in Wafer Size and Thickness: One of the technological advancements in the epitaxial wafer market is the increase in wafer size. Larger wafers allow for the production of more semiconductor devices, improving manufacturing efficiency. The shift towards larger wafers in the 9-12 inch range is a major trend in the market, especially in the production of power semiconductors and MEMS-based devices.

-

3D Epitaxy and 2D Materials: Innovations in 3D epitaxy and 2D materials are opening up new possibilities for the epitaxial wafer market. 3D epitaxy allows for the stacking of wafers, which increases the number of devices that can be fabricated from a single wafer. The use of 2D materials like graphene in epitaxial wafers is also gaining attention due to their potential for enabling ultra-thin, flexible, and highly conductive devices.

Challenges

-

High Production Costs: The production of epitaxial wafers is expensive due to the complex manufacturing process and the need for high-quality raw materials. The high costs associated with epitaxy equipment, materials, and processing are one of the major challenges facing the market.

-

Limited Availability of Raw Materials: The materials used in the manufacturing of epitaxial wafers, such as silicon and gallium nitride (GaN), are not only expensive but also limited in supply. The availability and pricing of these materials can affect the production and pricing of epitaxial wafers.

-

Environmental Concerns: The semiconductor manufacturing process, including epitaxy, generates waste and consumes energy, which has raised environmental concerns. The industry is under pressure to adopt sustainable practices to reduce its environmental footprint.

-

Competition from Alternative Technologies: As the demand for epitaxial wafers grows, the market faces competition from alternative semiconductor materials and manufacturing techniques. Technologies such as silicon carbide (SiC) and gallium nitride (GaN) are being explored as alternatives to traditional epitaxial wafers, posing a challenge to the market's growth.

Opportunities

-

Growth in Emerging Markets: The Asia Pacific region, particularly China, India, and Japan, is witnessing rapid industrialization and a growing demand for electronic devices and semiconductors. These regions present significant opportunities for companies in the epitaxial wafer market as manufacturing expands.

-

Technological Innovation and Customization: Companies in the market can differentiate themselves by offering innovative and customized epitaxial wafer solutions. Innovations in material properties, such as wide bandgap semiconductors for power electronics, are creating new opportunities for market expansion.

-

Integration of Epitaxial Wafers in Automotive and Renewable Energy: The growing demand for electric vehicles (EVs) and the increasing use of renewable energy technologies present significant growth opportunities for the epitaxial wafer market, particularly in the power semiconductor segment.

Epitaxial Wafer Market Segmentation

By Type

-

Heteroepitaxy

-

Homoepitaxy

By Wafer Size

-

2-4 Inch

-

5-8 Inch

-

9-12 Inch

-

Others

By Application

-

LED

-

Power Semiconductor

-

MEMS-Based Devices

-

Others

By Industry Vertical

-

Consumer Electronics

-

Automotive

-

Healthcare

-

Industrial

-

Others

By Region

-

North America

-

Europe

-

Asia Pacific

-

Latin America

-

Middle East & Africa

Key Players

-

Nichia Corporation

-

SUMCO Corporation

-

Soitec Belgium N.V.

-

Siltronic AG

-

Wafer World Inc.

FAQs

Q1. What is the growth rate of the epitaxial wafer market?

The epitaxial wafer market is expected to grow at a CAGR of 12.30% from 2025 to 2034.

Q2. What are the main types of epitaxial wafers?

The two main types are heteroepitaxy and homoepitaxy.

Q3. Which sectors are driving the epitaxial wafer market?

The LED, power semiconductor, and MEMS-based devices sectors are key drivers.

Q4. What challenges are the epitaxial wafer market facing?

Challenges include high production costs, limited raw materials, and environmental concerns.

Q5. What are the opportunities in the epitaxial wafer market?

Opportunities include expansion in emerging markets, technological innovation, and applications in electric vehicles and renewable energy.

- Vibnix Blog

- Politics

- News

- Liberia News

- Entertainment

- Technology

- Educaţie

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness