Automation Trends Powering Inline Automated Optical Inspection Market Growth

Introduction

The inline automated optical inspection system market is gaining significant attention across various industries. These systems are designed to detect manufacturing defects, measure quality, and ensure product consistency in real-time. By integrating advanced cameras, sensors, and software, they provide accurate inspection at high speeds, reducing errors and improving productivity.

In today’s competitive manufacturing environment, quality control is more critical than ever. Industries such as electronics, automotive, semiconductors, and medical devices rely heavily on these systems to maintain precision and reliability. Recent growth trends highlight the increasing adoption of Industry 4.0 technologies and automation, driving demand for inline optical inspection solutions. As global manufacturing evolves, these systems are becoming an integral part of production lines, ensuring efficiency, compliance, and customer satisfaction.

Stay ahead with crucial trends and expert analysis in the latest XYZ report. Download now: https://www.databridgemarketresearch.com/reports/global-inline-automated-optical-inspection-system-market

Market Overview

The inline automated optical inspection system market has experienced steady growth over the past decade. Historically, manual inspection was the primary method for ensuring product quality. However, this approach was prone to human error, time-consuming, and costly. With advancements in artificial intelligence, machine vision, and robotics, optical inspection systems have become a preferred choice for manufacturers.

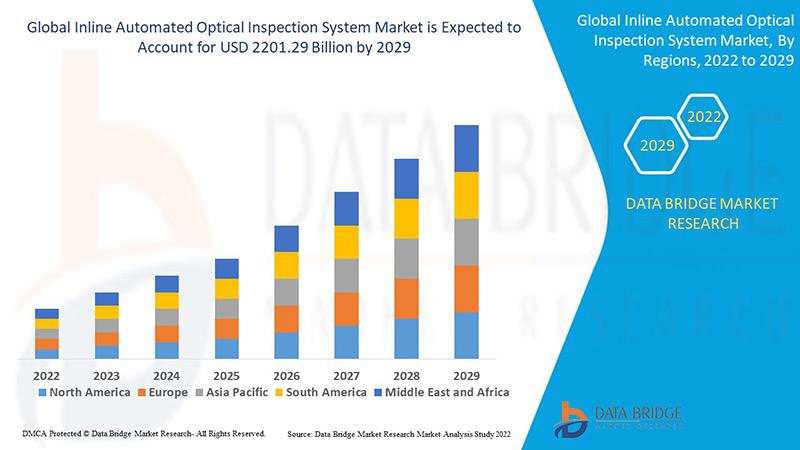

The market is expanding rapidly due to rising production volumes in electronics and semiconductors, especially with the growing demand for smaller, complex, and high-performance devices. Regions such as Asia-Pacific, particularly China, Japan, South Korea, and Taiwan, dominate the market due to their strong electronics manufacturing base. North America and Europe are also key contributors, driven by innovations in automotive, aerospace, and healthcare industries.

Future growth is expected to remain robust as manufacturers continue investing in smart factories and digital transformation initiatives. Increasing global emphasis on product safety and regulatory compliance will further strengthen market expansion.

Key Market Drivers

Several factors are fueling the growth of the inline automated optical inspection system market:

-

Rising Complexity of Electronics Manufacturing

The demand for miniaturized components and advanced semiconductor devices requires precise inspection. Inline AOI systems ensure defect-free production in high-density circuit boards and microelectronics. -

Industry 4.0 and Smart Manufacturing

The adoption of automation and connected systems in production processes has accelerated. AOI systems play a vital role in real-time monitoring and analytics, supporting predictive maintenance and quality improvement. -

Increasing Focus on Product Quality and Safety

Industries such as automotive and healthcare cannot afford defects due to safety concerns. Inline AOI ensures compliance with global safety standards and reduces the risk of recalls. -

Labor Shortages and Cost Efficiency

Rising labor costs and shortages of skilled workforce are pushing manufacturers to automate inspection processes. Inline AOI systems provide consistent accuracy without human fatigue. -

Supportive Government Regulations

Strict regulatory frameworks regarding product quality, especially in medical devices and electronics, are boosting the demand for automated inspection systems.

Market Segmentation

The inline automated optical inspection system market can be segmented by technology, application, end-user, and region:

-

By Technology

-

2D AOI Systems

-

3D AOI Systems

While 2D systems are widely used, 3D systems are rapidly gaining popularity due to their ability to provide depth measurement and enhanced defect detection.

-

-

By Application

-

PCB Manufacturing

-

Semiconductor Inspection

-

Automotive Component Inspection

-

Medical Device Manufacturing

-

Industrial Machinery

PCB manufacturing leads the segment, driven by increasing demand for consumer electronics and communication devices.

-

-

By End-User

-

Electronics and Semiconductors

-

Automotive

-

Aerospace and Defense

-

Healthcare

-

Industrial Manufacturing

The electronics and semiconductor industry dominates due to rising global demand for advanced chips and devices.

-

-

By Region

-

Asia-Pacific

-

North America

-

Europe

-

Latin America

-

Middle East & Africa

Asia-Pacific is the fastest-growing region, led by China, Japan, and South Korea. North America and Europe are also important markets, focusing on advanced manufacturing technologies.

-

Competitive Landscape

The inline automated optical inspection system market is competitive, with several global and regional players driving innovation. Key companies include:

-

Omron Corporation

-

Koh Young Technology

-

Test Research Inc. (TRI)

-

Mirtec Co., Ltd.

-

CyberOptics Corporation

-

Viscom AG

-

Camtek Ltd.

-

Saki Corporation

These companies focus on product innovation, strategic collaborations, and acquisitions to expand their market presence. For example, Koh Young Technology is recognized for its advanced 3D AOI solutions, while Omron has a strong footprint in smart factory automation. Many players are investing in AI-based AOI systems that improve defect recognition and adaptability.

Competition is shaping the market by encouraging companies to offer faster, more accurate, and cost-effective inspection systems. As customer demand grows, differentiation will rely on software integration, user-friendly interfaces, and real-time analytics.

Challenges and Restraints

Despite strong growth, the inline automated optical inspection system market faces several challenges:

-

High Initial Investment

Installing AOI systems requires significant capital, which can be a barrier for small and medium enterprises. -

Integration Complexity

Incorporating AOI into existing production lines can be challenging, requiring customization and technical expertise. -

Technological Limitations

Although advanced, AOI systems may sometimes struggle with highly reflective or complex surfaces, limiting accuracy. -

Shortage of Skilled Technicians

Operating and maintaining these systems requires skilled professionals, which remain in limited supply in some regions.

Future Outlook

The future of the inline automated optical inspection system market looks highly promising. The increasing adoption of artificial intelligence, deep learning, and machine vision technologies will enhance inspection capabilities. Real-time defect detection and predictive maintenance will become standard features, reducing downtime and improving efficiency.

The transition to 5G, smart devices, and electric vehicles will further drive demand for high-precision inspection systems. As sustainability gains importance, AOI systems will also support waste reduction by minimizing defective production. Additionally, cloud integration and data analytics will enable manufacturers to optimize processes and achieve higher operational excellence.

By 2030, the market is expected to see widespread adoption across both developed and emerging economies, transforming manufacturing industries worldwide.

Conclusion

The inline automated optical inspection system market is at the heart of modern manufacturing, ensuring precision, quality, and efficiency. Driven by the rising complexity of electronics, the shift toward Industry 4.0, and growing demand for safety and compliance, the market is expanding rapidly.

Although challenges like high investment costs and integration difficulties remain, the future is bright. With advancements in AI, machine vision, and automation, inline AOI systems are set to become indispensable for industries across the globe. Companies that embrace these technologies will be better positioned to compete in the fast-evolving manufacturing landscape.

Frequently Asked Questions (FAQs)

What is the growth rate of the inline automated optical inspection system market?

The market is expected to grow at a strong CAGR, driven by demand from electronics, semiconductors, and automotive industries.

Which region is expected to dominate the inline automated optical inspection system market in the future?

Asia-Pacific is expected to dominate due to its strong electronics manufacturing base, particularly in China, Japan, and South Korea.

Who are the leading players in the inline automated optical inspection system market?

Key players include Omron Corporation, Koh Young Technology, Mirtec Co., Ltd., CyberOptics Corporation, and Viscom AG.

What are the major challenges faced by the inline automated optical inspection system market?

Challenges include high setup costs, integration complexity, shortage of skilled professionals, and occasional technological limitations.

What are the future opportunities in the inline automated optical inspection system market?

Opportunities lie in AI-powered AOI, 3D inspection systems, cloud integration, and applications in EVs, 5G devices, and medical manufacturing.

Why is inline AOI important for manufacturers?

It ensures real-time defect detection, reduces waste, enhances productivity, and supports compliance with strict quality standards.

Browse More Reports:

Global Temperature Controlled Packaging Solutions for Pharmaceuticals Market

Global Therapeutic Bed Market

Global Thoracic Drainage Devices Market

Global Thyroid Cancer Drug Market

Global Tool Steel Market

Global Topoisomerase Inhibitors Market

Global Torque Limiter Market

Global Tortilla Chips Market

Global Toys Packaging Market

Global Tracheostomy Products Market

Title: Global Transportation Analytics Market

Global Transverse Myelitis Treatment Market

Global Traumatic Brain Injury Coma-Inducing Drugs Market

Global Traveler Security Services Market

Global Tropical Sprue Treatment Market

Global Turf Protection Market

Global Unijunction Transistor Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com

- Vibnix Blog

- Politics

- News

- Liberia News

- Entertainment

- Technology

- Formazione

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness