Pushing the Boundaries of Manufacturing with SLM 3D Printing Services

Introduction: A New Era in Metal Fabrication

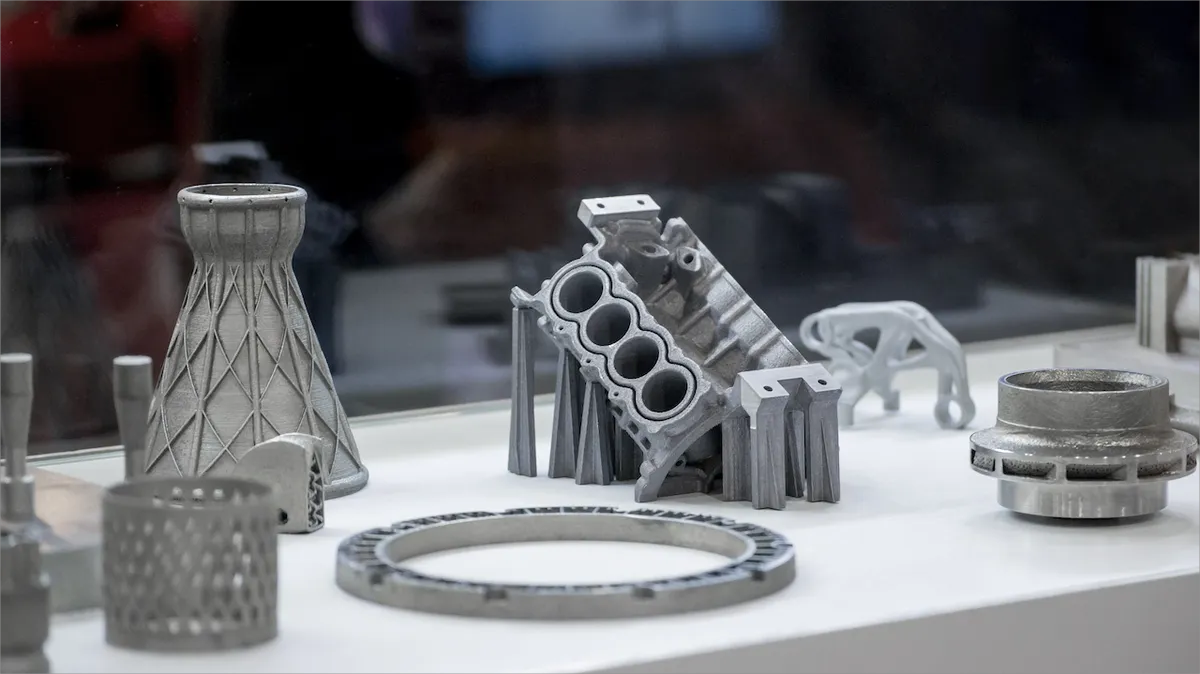

In today’s competitive manufacturing landscape, the need for faster, more precise, and more versatile production techniques has never been greater. One technology leading this transformation is SLM 3D Printing Services. By using advanced laser melting processes, industries can now create complex, high-performance metal components that were once impossible with traditional methods.

While many companies have embraced this technology, XC Machining has positioned itself as a trusted provider of Selective Laser Melting 3D Printing Services, ensuring quality, speed, and innovation in every project.

What Are SLM 3D Printing Services?

SLM 3D Printing Services use a powerful laser to fuse fine layers of metal powder into solid, three-dimensional parts. This additive manufacturing process enables unmatched design flexibility, allowing engineers to create geometries that would be too costly or complex using subtractive methods.

Key advantages include:

-

Design Freedom: The ability to produce intricate structures without the need for molds or tooling.

-

Material Strength: Components produced with SLM Metal 3D Printing Services retain exceptional mechanical properties.

-

Speed to Market: Rapid prototyping and production shorten the manufacturing cycle.

How Selective Laser Melting 3D Printing Services Work

The process behind Selective Laser Melting 3D Printing Services involves several precise steps:

-

Digital Model Preparation – Engineers create a CAD model of the part.

-

Powder Layering – A thin layer of metal powder is spread over the build platform.

-

Laser Melting – A high-powered laser selectively melts the powder based on the CAD design.

-

Layer-by-Layer Build – This process is repeated until the entire part is complete.

-

Post-Processing – Heat treatment, machining, or surface finishing is performed for enhanced performance.

This combination of precision and automation allows SLM 3D Printing Company services to deliver both prototypes and end-use components quickly.

Advantages of Custom SLM 3D Printing Services for Industry

For businesses that require tailored solutions, Custom SLM 3D Printing Services provide exceptional benefits:

1. Reduced Production Costs

By minimizing material waste and eliminating the need for molds, companies save significantly on production expenses.

2. Complex Design Capabilities

Engineers can create lightweight yet strong lattice structures, improving efficiency and reducing material use.

3. Faster Innovation Cycles

With Online SLM 3D Printing Solutions, businesses can quickly modify and test designs without halting production.

Applications of SLM Metal 3D Printing Services

The versatility of SLM Metal 3D Printing Services has made them popular in several industries:

-

Aerospace – For manufacturing lightweight, heat-resistant components.

-

Automotive – Producing custom performance parts and prototypes.

-

Medical – Creating patient-specific implants with high biocompatibility.

-

Industrial Machinery – Developing wear-resistant tools and machine components.

In each of these fields, SLM 3D Printing Services provide both strength and precision, helping companies stay ahead in their markets.

The Role of an SLM 3D Printing Company in Modern Manufacturing

An experienced SLM 3D Printing Company acts as more than just a service provider—it becomes a partner in innovation. This involves:

-

Material Expertise: Selecting the right alloy for each application.

-

Design Optimization: Ensuring parts are structurally sound and manufacturable.

-

Quality Assurance: Applying strict testing and inspection protocols.

XC Machining, while not relying on excessive branding, has demonstrated excellence in delivering Selective Laser Melting 3D Printing Services for clients worldwide.

Why Choose Online SLM 3D Printing Solutions

In today’s digital manufacturing era, Online SLM 3D Printing Solutions offer unprecedented convenience:

-

Remote Accessibility: Upload designs from anywhere in the world.

-

Instant Quotations: Receive cost and lead-time estimates quickly.

-

Global Collaboration: Work seamlessly with engineers and designers in different regions.

These features make SLM 3D Printing Services more accessible, helping businesses reduce turnaround time and improve competitiveness.

Customization: The Future of SLM 3D Printing Services

Customization is no longer a luxury—it’s a necessity for companies seeking unique product differentiation. Custom SLM 3D Printing Services enable manufacturers to:

-

Create one-of-a-kind components for specialized applications.

-

Improve functionality through tailored geometries.

-

Optimize part weight without sacrificing durability.

By integrating SLM Metal 3D Printing Services into their workflow, businesses can produce innovative, high-performance parts faster than ever before.

Quality Standards in Selective Laser Melting 3D Printing Services

For mission-critical industries, quality is non-negotiable. That’s why Selective Laser Melting 3D Printing Services often adhere to:

-

ISO Certification: Ensuring global manufacturing standards.

-

Material Traceability: Guaranteeing the source and grade of each metal powder.

-

Advanced Testing: Including X-ray inspection, tensile testing, and surface analysis.

Partnering with a reputable SLM 3D Printing Company ensures every part meets strict quality and safety requirements.

Sustainability Benefits of SLM Metal 3D Printing Services

Beyond efficiency and innovation, SLM Metal 3D Printing Services also promote sustainable manufacturing:

-

Reduced Waste: Material is only used where needed.

-

Energy Efficiency: Shorter production cycles save resources.

-

Lightweight Designs: Contribute to energy savings in transportation and machinery.

This environmentally conscious approach positions SLM 3D Printing Services as a forward-thinking manufacturing solution.

The Competitive Edge of SLM 3D Printing Services

Companies adopting SLM 3D Printing Services gain several competitive advantages:

-

Rapid Prototyping: Test and refine products quickly.

-

Mass Customization: Produce unique parts at scale.

-

Market Agility: Respond to customer demands faster.

Whether it’s through Custom SLM 3D Printing Services or Online SLM 3D Printing Solutions, the ability to innovate rapidly is what sets leaders apart from competitors.

Conclusion:

The manufacturing industry is evolving rapidly, and SLM 3D Printing Services are at the forefront of this transformation. With unmatched design flexibility, material strength, and production speed, these services empower businesses to create innovative, high-quality products that meet modern demands.

From Selective Laser Melting 3D Printing Services to Custom SLM 3D Printing Services, and from SLM Metal 3D Printing Services to Online SLM 3D Printing Solutions, the potential for growth and innovation is limitless. As industries continue to embrace this technology, those who adopt it early will enjoy the benefits of speed, quality, and market leadership.

- Vibnix Blog

- Politics

- News

- Liberia News

- Entertainment

- Technology

- Formazione

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness