Metal 3D Printing 2025: Innovations, Key Players, and Market Growth Insights

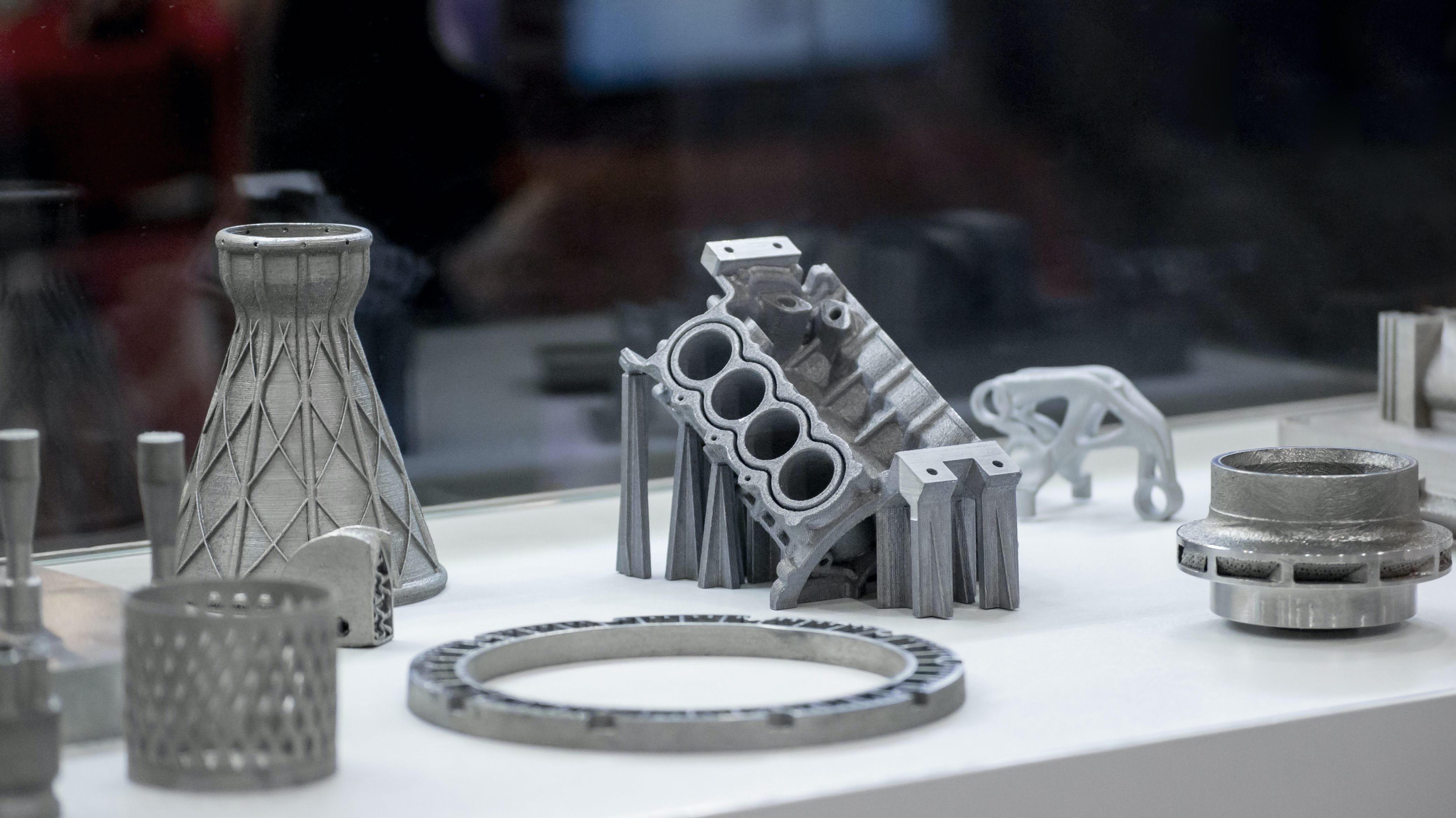

Metal 3D printing, also known as metal additive manufacturing, is transforming modern manufacturing by enabling the creation of highly complex and customized metal parts with improved efficiency and reduced waste compared to traditional machining methods. This technology uses layer-by-layer deposition of metal powders fused by lasers or electron beams to build intricate components that are otherwise impossible or costly to produce. Its growing importance spans industries such as aerospace, automotive, healthcare, and defense, where precision, lightweight design, and rapid prototyping are vital.

According to Straits Research, the global metal 3D printing sector was valued at USD 3.3 billion in 2021 and is projected to reach USD 20.96 billion by 2030, growing at a compound annual growth rate (CAGR) of 22.80% during the forecast period (2022–2030).

Recent Updates and Technological Advancements

Metal 3D printing is rapidly advancing with innovations in hardware, materials, and software. Powder bed fusion (PBF), including selective laser melting (SLM) and electron beam melting (EBM), remains the most popular technique due to its ability to produce parts with mechanical properties comparable to traditional manufacturing. Emerging technologies like directed energy deposition (DED) are gaining traction for printing larger components and repairing existing parts.

Artificial intelligence (AI) integration is proving transformative by enhancing design optimization, process control, and quality assurance. AI-driven generative design enables engineers to build lightweight yet structurally sound parts by iterating complex geometries automatically, often beyond human capability. Machine learning models analyze real-time printing parameters to detect and correct defects promptly, significantly reducing material waste and downtime.

Material variety is also expanding. Beyond standard stainless steel, titanium, aluminum, and cobalt-chrome alloys, researchers and companies are exploring refractory metals such as tungsten and molybdenum, which are increasingly needed in aerospace, defense, and energy sectors for their exceptional heat and wear resistance. Advances in powder quality and binder jetting techniques are improving printing speed and surface finish while lowering costs.

Key Players and Country-Wise Developments

-

United States: The U.S. hosts industry leaders investing heavily in multi-laser metal 3D printers and AI-driven software solutions. Companies collaborate with NASA, defense contractors, and automotive manufacturers to produce lightweight aerospace components and critical engine parts. Startups and established firms alike are scaling production capabilities for both prototyping and low to medium volume manufacturing.

-

China: China is aggressively growing its metal 3D printing capabilities with domestic firms developing cost-competitive systems targeting automotive and industrial applications. Government-backed initiatives support technology advancement and localized material supply chains. Collaborative efforts with global experts foster innovation, particularly in powder production and process automation.

-

Europe: European nations emphasize sustainability and precision engineering, with firms in Germany, the Netherlands, and the UK focusing on high-accuracy printers for medical implants and tooling. Collaborative R&D projects promote adoption of additive manufacturing in small and medium enterprises and integrate metal 3D printing into Industry 4.0 frameworks.

-

India: India is emerging as a dynamic market with startups and academic institutions advancing selective laser melting and direct metal laser sintering (DMLS) technologies. Focus areas include customized orthopedic implants and aerospace prototypes, supported by government programs enhancing manufacturing infrastructure.

-

Japan and South Korea: These technology leaders integrate metal 3D printing with robotics and smart manufacturing. South Korean companies pioneer large-scale printer development while Japan emphasizes quality control and materials innovation for electronics and automotive sectors.

Growth Drivers and Trends

The growth of metal 3D printing is driven by increasing demand for customization, lightweight structures, and rapid prototyping. The aerospace sector’s push for fuel-efficient, lightweight components fuels adoption, while healthcare benefits from patient-specific implants and surgical tools. Defense applications, including armor and missile components, are also accelerating technology uptake.

Sustainability concerns encourage manufacturers to adopt additive manufacturing for its reduced raw material waste and lower energy usage compared to subtractive machining. Hybrid manufacturing processes combining metal 3D printing with traditional methods are gaining popularity, offering a balance of efficiency and finish quality.

The COVID-19 pandemic underscored additive manufacturing’s value through rapid production of medical devices and ventilator components globally. This boosted investment and interest that continues to impact growth positively.

Challenges Facing Metal 3D Printing

Despite significant progress, challenges remain. High equipment and material costs limit widespread adoption, particularly for small and medium enterprises. The need for skilled operators and sophisticated design software also creates barriers.

Ensuring consistent quality and reliability of printed parts, especially for critical applications in aerospace and medical fields, demands rigorous testing and certification processes that are still evolving. Surface finish and post-processing steps can add time and costs.

Supply chain disruptions, including global tariffs on metal powders and high-precision manufacturing equipment, have added pressures since 2024. These impact pricing and availability, prompting companies to localize suppliers and increase R&D investment for alternative materials and manufacturing methods.

Complexity of integrating additive manufacturing into existing production workflows is another challenge, requiring substantial changes in design philosophy and quality assurance.

Recent Industry News

-

Eplus3D showcased a new generation of metal PBF printers with improved accuracy and speed at AMUG 2025, targeting aerospace and medical industries.

-

Intel and Freemelt collaborate on printing refractory metals like tungsten using EB-PBF for high-heat applications in energy and defense sectors.

-

Monarch Tractor and other OEMs increasingly apply metal 3D printed components in electric vehicle manufacturing, optimizing weight and strength.

-

Research centers in Europe and Asia are developing AI-powered quality control systems to monitor and correct real-time printing defects.

Summary

Metal 3D printing continues to revolutionize manufacturing by enabling complex, customizable, and lightweight metal components across major industries. Innovations in AI, materials, and printing technologies drive robust growth despite challenges around cost, certification, and supply chain pressures. Expanding regional capabilities and emerging applications affirm metal 3D printing’s central role in shaping the future of industrial production.

- Vibnix Blog

- Politics

- News

- Liberia News

- Entertainment

- Technology

- Formazione

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness