Best Soil Conditions for Horizontal Directional Drilling

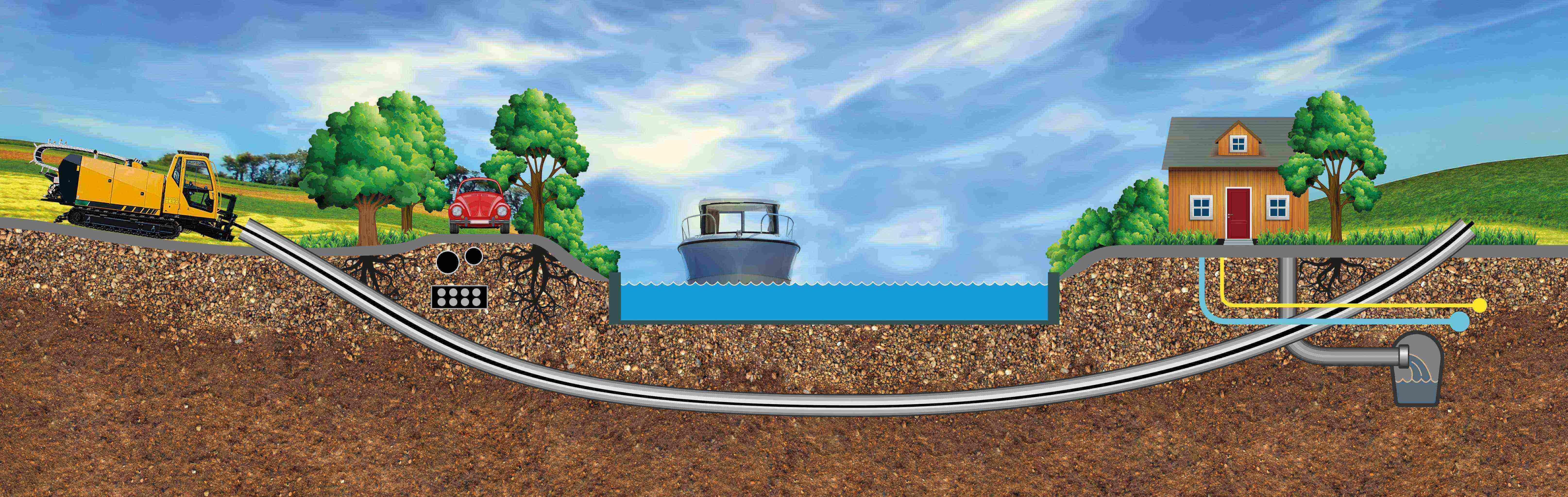

Horizontal Directional Drilling, also called HDD, is a special method used to install pipes, cables, or other underground utilities without digging long trenches. It is helpful for crossing roads, rivers, or busy areas without disturbing the surface.

But to make sure the job is done safely and smoothly, one thing matters a lot: soil conditions.

Not all soils are good for Horizontal Directional Drilling. Some are soft and easy to drill through. Others are hard or unstable, which can cause problems. That’s why it’s important to understand what kind of soil works best before starting any HDD project.

In this article, we’ll explain what types of soil are best for Horizontal Directional Drilling, which ones to avoid, and how to deal with difficult ground.

What Is Horizontal Directional Drilling?

Before talking about soil, let’s understand what Horizontal Directional Drilling actually is.

Horizontal Directional Drilling is a trenchless method. It involves three main steps:

-

Pilot Hole Drilling: A small drill bit creates a path underground from one point to another.

-

Reaming: The hole is widened using a special tool called a reamer to fit the pipe or cable.

-

Pullback: The pipe or cable is pulled back through the hole from the exit point to the starting point.

This process is done using a horizontal drill rig and needs proper planning and the right soil type to work well.

Why Soil Conditions Matter in Horizontal Directional Drilling

Soil is the ground you drill through. Its type, hardness, and stability can affect how easy or hard the drilling process will be.

Here are a few reasons why soil conditions are important:

-

Drilling Speed: Soft soils let the drill move faster.

-

Tool Wear and Tear: Hard or rocky soils wear out tools more quickly.

-

Borehole Stability: Loose or sandy soils may collapse, causing problems in the hole.

-

Accuracy: Some soil types make it harder to control the direction of the drill.

Choosing the right drilling method without checking the soil is like sailing without knowing the weather. It can lead to delays, damage, or even failed projects.

Best Soil Types for Horizontal Directional Drilling

Now let’s look at the types of soil that are most suitable for Horizontal Directional Drilling.

1. Clay Soils

Clay is one of the best soil types for Horizontal Directional Drilling. It is soft, sticky, and stable.

Advantages:

-

Good borehole support

-

Low risk of collapse

-

Easy to steer the drill

-

Holds its shape well

Clay is especially useful when using drilling mud (also known as drilling fluid) because it helps keep the hole open and clean.

Note: Some sticky clays may swell when wet, so you need to use the right mud mixture to control that.

2. Silty Clay and Sandy Clay

These are also good options. When clay is mixed with a bit of silt or sand, it becomes easier to drill through while still keeping good stability.

Advantages:

-

Soft enough for quick drilling

-

Not too loose

-

Supports borehole shape

Make sure to test the mixture of the soil before starting. Too much sand or silt can cause the ground to become unstable.

3. Firm, Fine Sand

Fine sand is okay for Horizontal Directional Drilling if it is firm and packed tightly.

Advantages:

-

Easy to drill through

-

Low equipment damage

Challenges:

-

Borehole may collapse if the sand is too loose

-

Needs careful fluid pressure to hold the hole

With the right drilling mud and steady speed, sand can be managed.

Soil Conditions That Are Difficult (But Possible)

Some soil types are not ideal, but with the right tools and planning, you can still complete HDD projects in these conditions.

1. Gravel

Gravel is made of small rocks and stones. It can be tricky.

Problems:

-

Drill may bounce or get stuck

-

Hard to keep borehole shape

-

High wear on tools

Solution:

-

Use stronger drill heads

-

Use thicker drilling fluid

-

Drill slowly and carefully

Small amounts of gravel mixed with other soils may be okay, but large gravel beds can be risky.

2. Loose Sand

Loose, dry sand is one of the most difficult soils for Horizontal Directional Drilling.

Problems:

-

Borehole may collapse

-

Drill path may be hard to control

-

Water can wash sand into the hole

Solution:

-

Use special drilling fluids to support the hole

-

Keep fluid pressure steady

-

Add stabilizers if needed

If sand is mixed with clay, it becomes easier to work with.

3. Rock and Cobble

Hard rock or cobble (large round stones) is very challenging.

Problems:

-

Slow drilling speed

-

Very high wear on equipment

-

Hard to steer or control direction

Solution:

-

Use rock drilling heads (with carbide or diamond bits)

-

Increase machine power

-

Be ready for longer project times

HDD in rock is possible but needs expert skills and planning.

How to Check Soil Before Drilling

Before starting any Horizontal Directional Drilling job, you should always do a soil test. This process is called a geotechnical survey or soil investigation.

Here are some ways to check the soil:

-

Soil Boring: A small hole is drilled to bring up soil samples.

-

Test Pits: A shallow pit is dug to see soil layers.

-

Lab Testing: Soil is sent to a lab to check texture, strength, and water content.

Once you know the type of soil, you can decide how deep to drill, what tools to use, and how to mix your drilling fluid.

Tips for Drilling in Any Soil Type

-

Always plan ahead with proper soil data

-

Use the right drilling fluid to support the borehole

-

Choose the best drill head for your soil

-

Monitor pressure carefully during drilling

-

Train your crew to handle unexpected conditions

Final Words

Horizontal Directional Drilling is a smart way to install underground utilities with minimal surface damage. But to do it successfully, you need to understand the soil you’re drilling through.

- Vibnix Blog

- Politics

- News

- Liberia News

- Entertainment

- Technology

- Образование

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness