Cap Compression Molding Machine Price Reflects Process Versatility

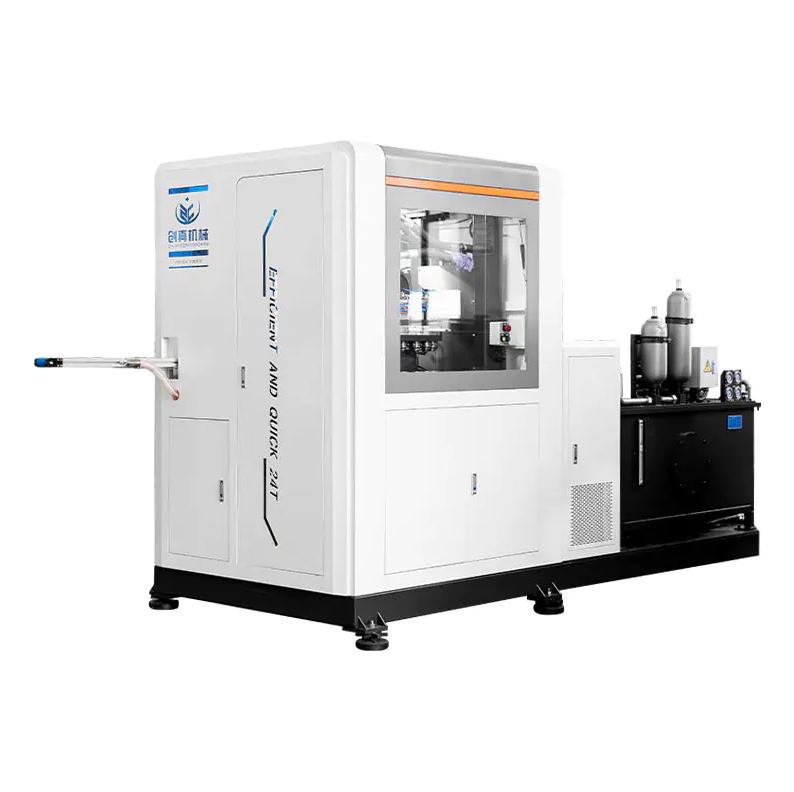

As packaging companies explore leaner, more responsive production methods, the value of accurate and energy-conscious molding processes is increasingly clear. The shift has placed systems like the Cap Compression Molding Machine Price at the forefront of capital planning. While cost considerations remain, the conversation has expanded to include flexibility, uptime, and long-term performance assurance.

Evaluating the Cap Compression Molding Machine Price now involves more than upfront expenditure. Buyers analyze the machine’s adaptability across cap designs, mold switching ease, and integration with existing automation systems. With high-speed output and reduced thermal stress on resin, compression molding fits naturally into sectors that demand uniformity and tight tolerances. This includes bottled water, dairy packaging, health supplements, and chemical containers.

A driving force behind the technology's popularity is its ability to form caps with better mechanical consistency and finish. Unlike injection systems, compression molding applies less force and lower temperature variations, leading to smoother surfaces and fewer internal stresses. In a competitive market where packaging appearance and function influence customer perception, even minor advantages in quality can drive brand preference and reduce returns.

Technology updates also support a new level of precision and operational transparency. Modern systems now come equipped with digital interfaces, predictive maintenance modules, and enhanced alignment for each mold cavity. For operations targeting zero-defect output, these tools offer measurable gains. They reduce human error, flag anomalies in real-time, and help schedule tooling maintenance before failure impacts productivity.

On the production floor, machine speed is important—but so is energy efficiency. Compression molding requires less heating and cooling time per cycle, significantly lowering electricity usage per part. This environmental gain doubles as a cost advantage, especially when producing tens of thousands of units per hour. With global regulatory bodies pushing for greener operations, such efficiency metrics carry weight in purchasing decisions.

Taizhou ChuangZhen Machinery Manufacturing has become a respected name in compression technology by delivering solutions tailored to the evolving needs of cap producers. Their systems reflect both practical factory input and forward-looking R&D. Whether it’s improving cap ejection speed, enhancing mold cleaning access, or adjusting cavity pressure balance, their approach focuses on production ease and repeatability.

Clients across industries increasingly expect not just machinery but an intelligent production partner. This means a company that provides ongoing training, helps improve cycle designs, and offers remote diagnostics and part support. ChuangZhen’s dedication to full-lifecycle customer service makes it easier for manufacturers to scale while maintaining output consistency.

For companies investigating options or reevaluating current compression lines, the discussion around machinery investment now includes detailed benchmarks, reliability comparisons, and operator ergonomics. Investing in the right system affects product quality, packaging speed, and margin control across every product line.To gain further knowledge on advanced molding technologies, pricing structures, and system configurations, please refer to the official knowledge base at www.capping-machine.net/news/industry-news/cap-compression-molding-machines-price-types-process-and-future-trends.html

- Vibnix Blog

- Politics

- News

- Liberia News

- Entertainment

- Technology

- Educação

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness